Information about Led Tube Light

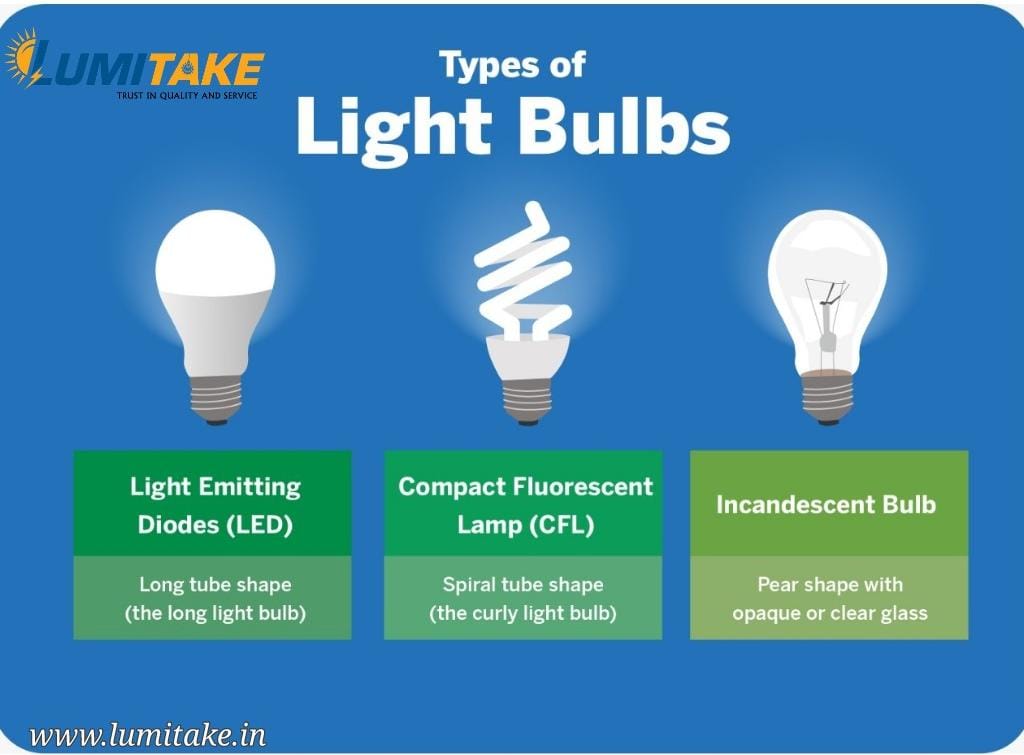

LED Tube Light Guide For decades, tube lights have provided excellent illumination capabilities for a variety of commercial and industrial environments, from office spaces to warehouses and workshops. Their versatility is one of their biggest selling points, as the fixtures they are mounted in can be hung, suspended in a drop ceiling or even mounted directly to a flat ceiling surface. Additionally, they are inexpensive to install and operate, which when combined with their strong lumen output and wide angle of spread, makes them one of the most popular lighting options in the lighting industry. In this guide we will be focusing on the specifics of LED tube lights, including the wide variety of options available in today’s marketplace. LED Tubes v.s Fluorescent Tubes Commercial office space with cubicle is illuminated by overhead LED troffer lighting recessed into the drop ceiling Traditionally, these tube lights have been of the fluorescent type, which uses low-pressure mercury-vapor gas discharge technology to generate light when electricity is passed through it. While this served many businesses well for decades, it is now considered outdated, inefficient and even environmentally hazardous due to the mercury contained within. As the fixtures themselves age, they also require additional maintenance, such as the replacement of the ballasts required to run the lamps. On top of all of this, the light produced by fluorescent lamps is regarded as subpar, with a consistent flicker from the light switching on and off at approximately 120 Hz that causes eye strain over long periods of time. It is for the aforementioned reasons that LED tubes have come to completely dominate the lighting marketplace for new installations as well as the retrofit of existing fixtures. LED technology in tube lights resolves all of these concerns, and also adds some additional welcome benefits. When used in tube lights, LEDs offer a longer lifespan, are more energy efficient, contain no toxic substances and also produce a much higher quality of light with less eye strain and greater visibility thanks to their high CRI ratings. Tube Sizes There are a variety of shapes, lengths and diameters in tube lights in order to suit a wide range of applications. Generally speaking, with LED tubes the most common size and shape are the 4 foot length fixtures with a T8 diameter. Other lengths available in the marketplace include 2 foot, 3 foot and 8 foot. In the past, T12 diameter bulbs were the standard, eclipsed first by T8 and then T5. For older fluorescent fixtures, the most common setup is going to be either a T12 or T8 type due to the costs associated with running T5 fluorescent light fixtures. When upgrading older existing fixtures, sometimes the issue arises where it is unclear what diameter bulb is currently installed. Luckily, this is an easy fix as the labeling system is standardized across all manufacturers. The “T” stands for tubular, referring to the bulb’s shape, and the number following it represents the bulb diameter in eighths of an inch. This means a T8 bulb will be 1” in diameter, while T12 and T5 bulbs will be 1.5” and ⅝” in diameter respectively. It should be noted that as long as a T8 and T12 are using the same pin base (G13 most likely), they can be used interchangeably, as long as they are within the same milliamp requirements for the ballast if it is using one. Below is chart that illustrates the various sizes and base types for tube lights: Color Temperatures After selecting the correct size and type of tube, buyers will have multiple options for color temperature ranges. Color temperature is the hue or color of the light produced, and is measured using the Kelvin (K) scale which usually ranges from 2400K to 6500K. In the LED lighting marketplace, the typical color temperatures available are normally 2700K, 4000K, 5000K and 6000K. The lower the color temperature, the warmer or more red the light becomes. On the opposite end of the color temperature range, the light becomes white and then blue in its hue. For offices and general workspace use, the 4000K range is one of the most popular, with a “cool” white color. For areas requiring a daylight equivalent such as high-security areas, garages, parking structures, private roads, alleyways and general display areas, 5000K is the top choice. Below we have included a chart that details these different color temperature ranges and their applications: Installation While installation in most cases is pretty straightforward, there is the possibility that rewiring will be required, such as with direct wire tubes. Because of this, we strongly recommend working with a licensed electrician experienced in LED retrofitting. This will not only ensure the best lighting performance but also make certain that the installation was completed safely. The best way to find an electrician is via a directory, which can be narrowed down by state or province, depending on whether the installation is in the United States of Canada. Below are a couple of directories that can help in this search https://straitslighting.com/blog/news-item/tube-lighting-guide/

.jpg)